What Size Flux Core Wire For Body Repair

There isn't a major difference between the 0.030 and 0.035 flux-cored wires. But each is more suited for specific applications.

These differences mainly revolve around the thickness of the material, welding auto abilities, and the specific utilize cases where one may be ameliorate than the other.

In this article, you will learn which wire is better in sure situations. As a bonus, you might fifty-fifty discover a thing or two about flux-cored wires in general.

What is Flux-Cored Wire?

A flux-cored wire is essentially a tube packed with a flux substance in its core. It's similar a stick electrode turned inside out. This flux is a compound mixture of alloys and deoxidizers that allow users to weld dirtier metal and it be used in windy conditions.

Flux generates shielding gasses when flux-core welding, which protects the molten weld pool from oxygen and nitrogen and stabilizes the arc. Information technology also collects the impurities in a layer of slag on top of the bead, which is chipped off afterward the weld cools downward.

The deoxidizers found in cored wires are typically aluminum and magnesium. Once exposed to gasses in the atmosphere, deoxidizers course aluminum oxide, aluminum nitride, and magnesium oxide. These newly formed compounds solidify rapidly on the weld surface and protect the bead from atmospheric contagion.

Finer, the two typical weld contaminants (oxygen and nitrogen) transform into protective compounds. That's why no shielding gas is necessary when using a flux-cored wire. This applies only to self-shielded flux-cored wires (FCAW-Southward), which most people are using.

These wires are available in many different diameters including 0.030" and 0.035". In improver, they can be used in all positions or apartment/horizontal only.

Cored wires are typically manufactured by taking a thin strip of steel and rolling information technology in a "U" shape. Flux is poured into the cavity and the seam is tightly rolled closed. The seam can be either a lap or a butt joint. The lap articulation is somewhat more secure against moisture contagion.

The outer tube of the wire is called the "jacket" or "sheath," while the mixture inside is called the "flux-core."

Near cored wires are designed to work with straight current electrode negative (DCEN), which is the opposite of solid steel MIG wires. Then, y'all will have to switch polarity between your MIG gun and the ground clamp when changing over to flux-cored wire.

0.030 vs. 0.035 – Which I Should You Use?+

Side-past-Side Comparison

Let'due south compare these two diameter flux-cored wires side by side past using some full general metrics. It's difficult to compare real-world products because most of them don't provide the necessary data.

| 0.030" | 0.035" | |

|---|---|---|

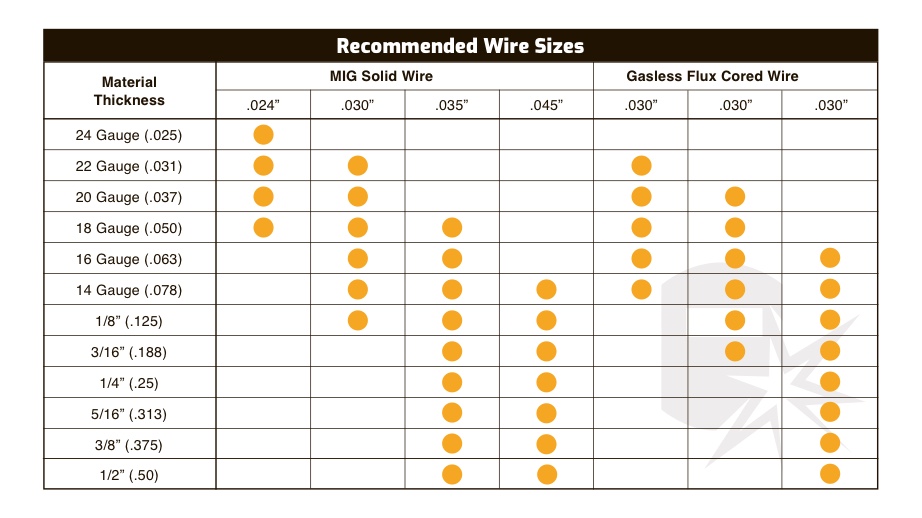

| Textile Thickness Range Single Laissez passer (mild steel) | 22 Gauge (.031") – 14 Judge (.078") | 20 Gauge (.037") – 3/16" (.188") |

| Required Volt Range ** | 17 – 20V | eighteen – 24V |

| Wire Feed Speed Range ** | 170 – 215 ipm | 170 – 350 ipm |

| Smoke and Spatter Amount | Less | More |

| Amount of Shielding Flux | Less | More |

| Wire Stick-out | Shorter | Longer |

** Every welder volition vary slightly.

Allow's dig in a little deeper to explore the differences between these ii cored wire thicknesses in existent-world examples.

I will explain both wires in a general manner. Just be aware that specific brands can provide different results. The chemical compounds and manufacturing processes vary between dissimilar production plants.

0.030 Flux-Cored Wire

The 0.030" diameter flux-cored wire is a typical hobbyist-level wire meant for thinner metal. Information technology's primarily used for light welding piece of work outdoors or by people who don't want to carp with the whole MIG shielding gas setup.

It will weld annihilation between 22 gauge and 14 gauge thick. You lot can fifty-fifty try 24 gauge, merely it tin can atomic number 82 to burn-through. Welding thicker than 14 gauge is possible with multiple passes, simply but if the wire is designed for information technology.

This wire will perform all-time if you utilize it with 210V input. It likewise works fine at 120V, but you should employ a higher voltage to burn it hot and become the best penetration.

So, let's take a look at Lincoln'southward Innershield NR-211MP (AWS – E71T-eleven), one of the tiptop-rated, standard 0.030" cored wires for all position welding.

The offset thing to note is that its spec sheet says explicitly that all diameters under 0.045" tin't weld above 5/16". That ways that yous tin't weld thicker with the 0.035". If you spend a few hours reading through various Lincoln Electric documents on their website, you'll discover that this is because of the generated heat.

If you weld metallic thicker than recommended, the arctic charge per unit of the weld volition be also fast for the wire'due south pattern. The high thermal conductivity of the thicker base metal induces rapid cooling, which leads to cracks cheers to brittleness caused by weld quenching.

Nevertheless, 0.030" wire produces less smoke and spatter thanks to its lower amount of flux. Additionally, the thinner flux, and tubular steel walls, require less amperage and voltage for maximum oestrus. And so, a weaker machine will run them slightly meliorate than the 0.035".

Suppose your welder is not very powerful. In that instance, the 0.030" volition carry voltage meliorate, and the arc will have a more stable beliefs. Cored wires are very sensitive to voltage fluctuations.

Conversely, the 0.035" wire requires slightly more than voltage, which if not provided, volition pb to arc cone shortening and reduction of the bead'due south width. This can atomic number 82 to burn-though or poor penetration depending on the metal and amperage output of your welder.

The 0.030" is also a good selection when welding in tight corners because you'll deposit less metal and exist able to see the weld pool more clearly. It is too cheaper and gives you more wire length per pound.

0.035 Flux-Cored Wire

The 0.035" cored wire offers slightly more welding power, provides a higher estrus input into the metallic, and better penetration.

Compared to the 0.030" this thicker diameter is used in similar environments. Just with a higher flux content, it tin can better withstand windy weather. That's why a 0.035" wire produces better results when welding outside. Depending on the wind forcefulness and arc quality, the 0.030" wire may non prevent all of the oxygen and nitrogen from weld contamination.

This wire tin weld a maximum of iii/16" and down to 20 gauge steel as a minimum. Since it applies more heat to the metallic, y'all are unlikely to weld annihilation thinner than the recommended 20 judge.

To become the most out of this diameter, you should utilise a machine with 250V input. It tin can work well with less voltage, too. But, poor cable connections, long power cables, undersized cables, poor welding clamps, and the efficiency power rating of the welder will all bit abroad at the available voltage. So, if you want to run it hot for maximum penetration, it needs a loftier voltage input.

If we look at Hobart's 0.035" E71T-xi cored wire, nosotros'll see that they don't provide every bit many specs as Lincoln. In such cases, information technology's all-time to stick to the recommended thicknesses I talked near above.

Hobart'south wire allows for multi-pass welds, galvanized steelwork, and all-position welding like Lincoln's.

But this wire has a higher aluminum and a lower manganese content, making Lincoln'south wire a ameliorate choice. A higher manganese content refines weld microstructures and promotes acicular ferrite formation. The written report from 1980 by the American Welding Guild (AWS), constitute that the increased presence of manganese increases both tensile strength and yield strength.

However, the same report found that strain aging significantly affects the notch toughness when higher manganese content is present. This means that any flaw in the weld, like a notch or a crack, is less likely to sustain stress under load when this Hobart wire is used.

So, while Lincoln'southward wire is a fleck better, it needs a perfect weld dewdrop for its loftier manganese content to brand a difference.

The 0.035" produces more smoke and welding spatter due to the additional flux and steel content. So if yous are looking for a cleaner weld, y'all should use 0.030" when possible. Merely unlike the 0.030", the 0.035" will deposit more metal and makes for a better option when welding gaps.

Smaller-diameter wires crave less stick-out, so the 0.035" is better if you are all the same learning. Having a bigger stick out gives you more oversight of the bead because the tip is not as shut to the weld puddle.

Wrapping Information technology Up

As merely presented, there are subtle differences betwixt these ii "flavors" of flux-cored wire. Knowing what they are can help y'all know which to use in certain situations. That results in meliorate quality welds.

Just if you are a hobbyist welder, the slight variation in these two different diameter flux-cored wires will non make a huge difference. You are more likely to experience problems if using a poor-quality wire.

However, equally you've seen, these wires do have their differences. If you are welding something delicate, even as a hobbyist, you can benefit from a proper wire selection. I promise that this article helps you do just that.

If it did, delight share it with your welder friends. These nuances are rarely discussed on the net, then maybe they'll larn something new as well.

What Size Flux Core Wire For Body Repair,

Source: https://weldguru.com/030-vs-035-flux-core-wire/

Posted by: greenequareatunto.blogspot.com

0 Response to "What Size Flux Core Wire For Body Repair"

Post a Comment